Wheat flour handling equipment provider in India: Knitcons

Wheat flour handling system is an important aspect of the food industry in India. India is the second-largest producer of wheat in the world, and as a result, the country has a significant wheat flour processing industry. We all knows that Wheat flour is an important source of carbohydrates. It is the leading source of vegetable proteins, having a protein content of about 13%, which is relatively high compared to other major cereals. In particular, the unique properties of the gluten protein fraction allow the processing of wheat flour to produce bread, other baked goods, noodles and pasta, and a range of functional ingredients.

In India, 65% of the population consumes wheat flour, making it the second most important staple food after rice, and this number is anticipated to rise further due to changes in dietary preferences. A fundamental raw ingredient, wheat is employed in numerous areas of the food business. Wheat is a basic raw material used in many different sectors of the food industry.

Exploring the Multi-Step Process of Wheat Flour Handling in India

Wheat flour handling involves several steps, including transportation, storage, and processing. Let's analyze a few crucial steps.

A] Wheat Flour Transportation

Transportation is the first step in the wheat flour handling system. In this process, Tanker Loading and Unloading System plays a major role. because they are efficient, safe, and hygienic as well. The closed system reduces the risk of contamination and spillage, ensuring that the wheat flour arrives at its destination in the same condition as when it was loaded.

i] Flour Tanker Loading System

The tanker truck arrives at the wheat flour mill or storage facility and is positioned at the loading point. A loading arm or hose is connected to the tanker, and wheat flour is pumped into the tanker from the mill or storage facility. The loading process is monitored to ensure that the tanker is not overfilled.

ii] Flour Tanker Unloading system

The tanker truck arrives at the destination (e.g., a bakery or food processing plant) and is positioned at the unloading point. The tanker is connected to a discharge hose, and the wheat flour is pumped out and into the plant's storage silos or processing equipment.

B] Wheat Flour Storage Silos

After transportation, wheat flour is stored in silos or storage containers before it is used in the bakery or food processing plant. The storage containers used in India are typically made of steel or concrete and are designed to prevent contamination and protect the wheat flour from moisture and pests.

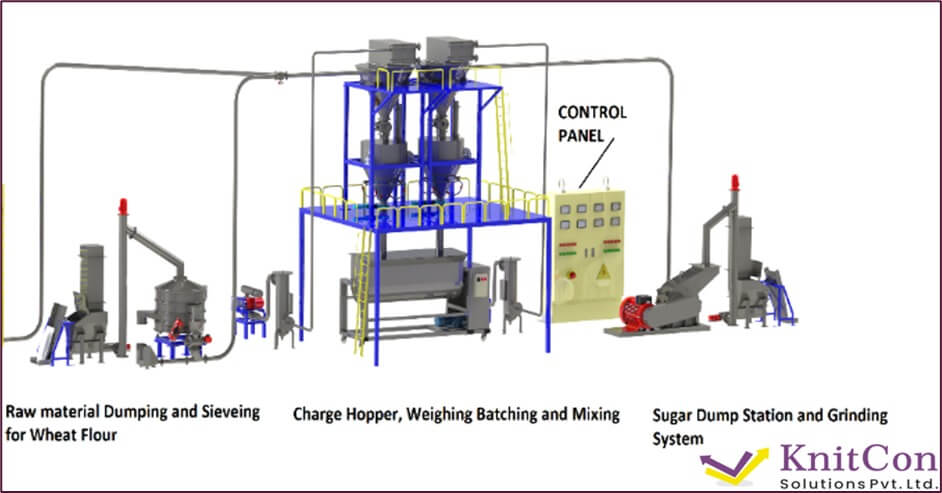

C] Wheat Flour Processing

After transportation, wheat flour is stored in silos or storage containers before it is used in the bakery or food processing plant. The storage containers used in India are typically made of steel or concrete and are designed to prevent contamination and protect the wheat flour from moisture and pests.

The Function of Pneumatic Conveying Systems in Wheat Handling Equipment

Pneumatic conveying systems are frequently employed in India's wheat flour handling system because of their effectiveness, dependability, and hygienic operation. Materials can be moved quickly and effectively using air pressure in pneumatic conveying systems. In the quick-paced atmosphere of a bakery or food processing facility, this means that ingredients like flour can be delivered swiftly from one place to another. In addition to being enclosed, pneumatic conveying systems allow for hygienic operation. In the food business, where cleanliness is crucial to preventing contamination and ensuring food safety, this is significant.

Pneumatic conveying is chosen depending on site-specific factors. The finest kind of pneumatic conveying system for the use of wheat flour is a lean-phase pneumatic system, also known as a dilute-phase pneumatic system.

There are two types of dilute-phase pneumatic system

Positive Pressure Type

Positive pressure systems are used to transport bulk goods over medium distances with a higher capacity than hoover systems since they operate above atmospheric pressure.

With diverter valves, multiple destination deliveries, one after the other, can be arranged easily with positive pressure systems.

Moreover, many input points into a single line can be offered to guarantee proper air quantity, valve selection, and customized conveyance Rotary air lock valves.

Vacuum/Suction/Negative Pressure Type

Negative pressure conveying systems operate with air pressures below atmospheric pressure. The material is drawn into the air stream through a suction tool or the Rotary Airlock Valve (RAL) by applying hoover pressure at the desired location. The benefit of internal gas leakage is that atmospheric dust injection is all but eliminated.

A negative pressure system is critical for toxic and explosive materials, and these materials can operate without a closed system, provided adequate safety measures like exhaust venting are taken care of.

Operations for processing wheat flour

- Unloading

- Transferring

- Storage

- Screening

- Classifying

- Magnetic separation

- Conveying

- Blending

Advantages

- Free

- Since it is in powder form, no chance of

- Low air pressure

Conveying Challenges

- Hygroscopic in nature, maintain plant humidity under set conditions.

- Can be sticky on the absorption of

- Need to separate from air using a suitable filter.

- can catch fire

Benefits

- Can be picked up from multiple points and conveyed to multiple

- Reduction in batch time and process

- Low Operating Cost as Air Consumption Is

- can be designed to meet any

- Safe way of dust free

Applications

- Food Industry

- Bakery Industry

- Confectionary Industry

- Biscuit Industry

In India's wheat flour handling system business, Knitcon Solutions Pvt . Ltd is a leader in the provision of top-notch solutions. Team Knitcons recognizes that each business is distinct, which is why we approach our service with a personalized approach. Our team works hard with each customer to fully grasp their unique demands and requirements before customizing our solutions. We have the knowledge and capabilities to provide the ideal solution, whether you need a full wheat flour handling system or just a single part. We have faith in our ability to present the ideal answer for your company's requirements. Get in touch with us right now to find out more about how we can help your company succeed.