Ribbon Blender Manufacturer in Pune, India: Knitcons

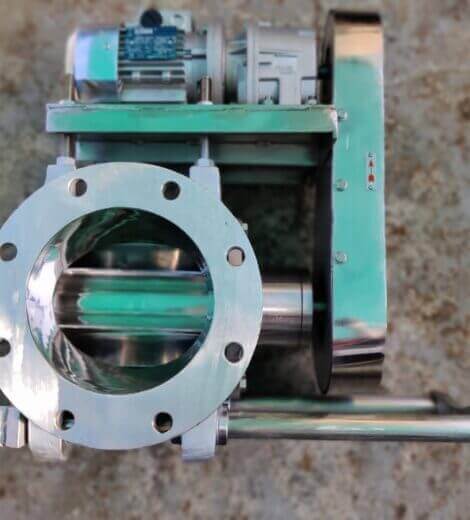

A ribbon blender consists of a U- trough horizontal containing a double helical ribbon. The ribbons shaft is positioned in the center of the trough. Which the helical ribbons consist of a set of inner and outer helical ribbons.

The internal and external ribbons on the shaft located with the blender trough. The ribbon shaft is powered by a drive system comprised of a motor, gearbox, and couplings.

Ribbon blenders can be designed to operate in both

batch and continuous modes. Its ability to perform heating, cooling, coating and other processes make it a very popular blender.