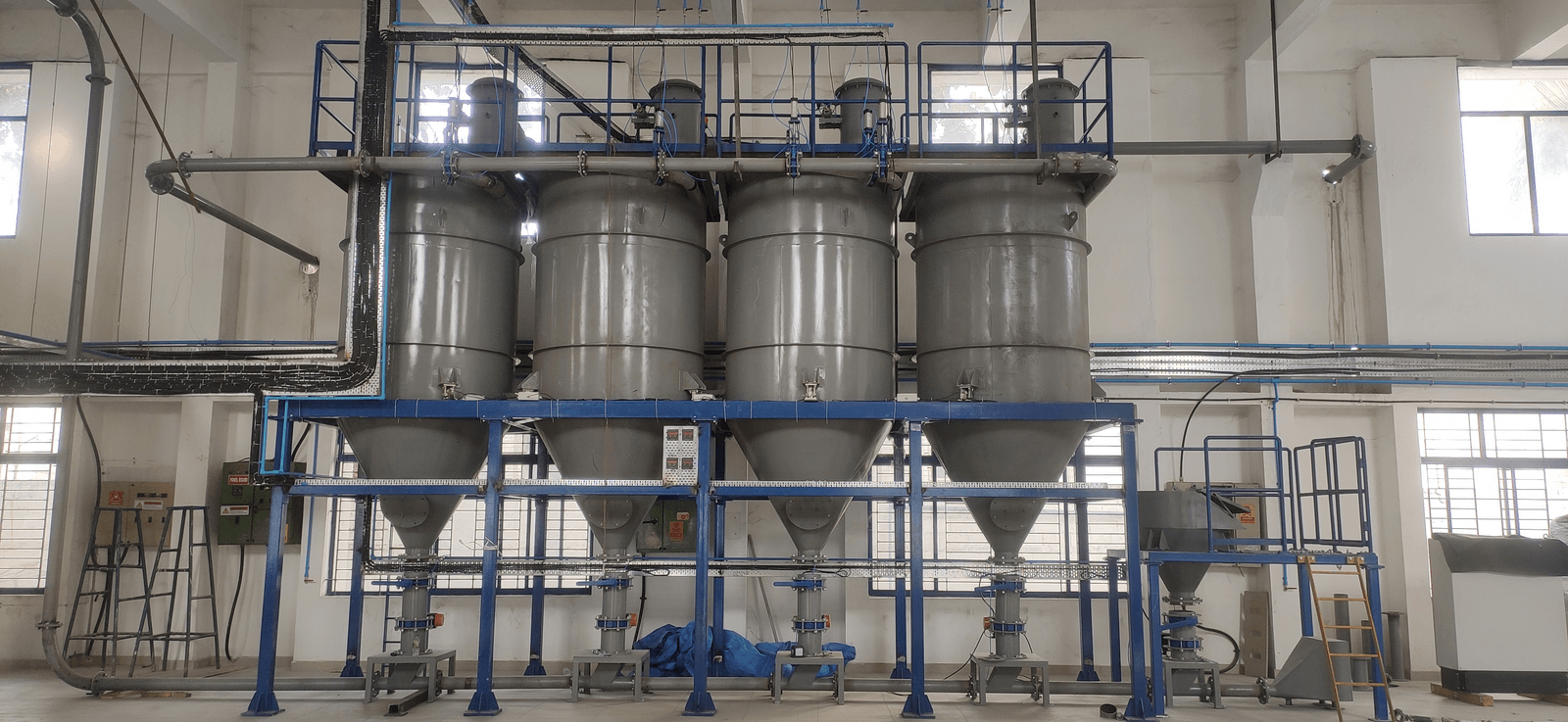

Knitcons Engineering is one of the leading storage silo manufacturers in India, offering advanced and fully customized silo storage systems designed for maida, flour, grains, and powder handling.

Our silos are engineered for durability, hygiene, and seamless integration with pneumatic conveying systems ensuring smooth, contamination-free, and automated operations.

What Is a Silo Storage System?

A silo storage system is a high-capacity, vertical container engineered to safely store bulk

powders, grains, and fine materials.

At Knitcons, our silos are designed for efficient storage, discharge, and transfer, ensuring

zero

contamination and minimal product loss.

Whether for flour milling, grain storage, or chemical applications, our systems are built to

deliver clean, dust-free, and energy-efficient performance.

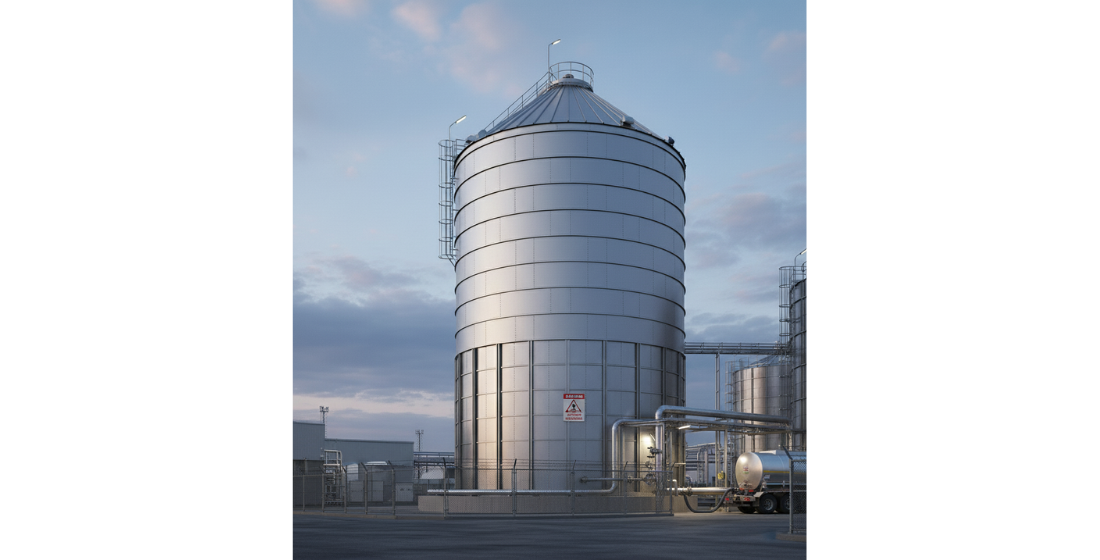

Maida / Wheat Flour and Sugar SS304 Storage Silo

with Tanker Unloading System

Efficient bulk material handling plays a crucial role in maintaining product quality and operational hygiene in food manufacturing. We design Maida / Wheat Flour and Sugar Handling System, offers a fully automated and dust-free solution for conveying, storage, and process feeding of fine powders.

The system is designed for direct unloading from bulk tankers to the Storage Silo and Small Bags with the help of Bag Tilter, further transfer to the Storage Silo using pneumatic conveying system, ensuring a clean and contamination-free transfer of Maida and Sugar to SS304 Storage Silos. Material from both sources is conveyed through a closed pneumatic pipeline into food-grade Silos equipped with aeration pads, bin activators, load cells, and vent filters to maintain smooth flow and precise level control. From the silos, material is transferred through automated weighing and batching systems to the downstream process line, ensuring precise recipe control and consistent product quality, consistent feed, minimal material loss, and a completely dust-free operation throughout the handling system.

System Highlights

- Automated Tanker Unloading: Dust-free pneumatic conveying directly from bulk tanker to silo.

- Hygienic Storage: Food-grade SS304 silos with fluidizing system for smooth discharge.

- Loss-Free Transfer: Closed conveying ensures zero spillage and minimum product degradation.

- Ease of Operation: Fully integrated controls for loading, storage, and batch feeding.

- Low Maintenance & High Reliability: Designed for continuous, trouble-free operation.

This integrated solution finds wide application in Food, Bakery, Confectionery, Biscuit, Beverage, Instant Mix, Noodles & Pasta, Spice Processing, Dairy Powder, Pharmaceutical, Nutraceutical, and Chemical Industries for efficient bulk handling of Maida, Wheat Flour, Sugar, and other fine powders or granular ingredients.

Accessories for Silo Storage System

- Ladders, stairs, and other accessories

- Reverse Jet Filter /Bin vent filters and receivers

- Pressure Relief Valves

- Explosion suppression and venting

- Load cell System for Scaling

- Level Devices (high and low)

- Custom inlets and outlets

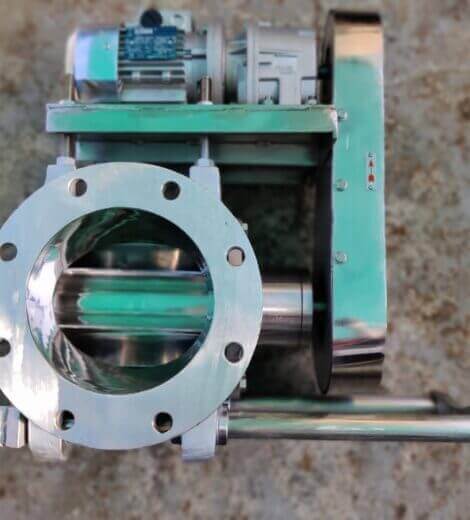

- Vibratory bin dischargers, hopper fluidization, and multiple screw bottoms transportation to the plant site

Each Knitcons Maida storage silo system is equipped with advanced sensors, load cells, and discharge vibrators for accurate weight monitoring and smooth material flow.

Types of Storage Silos:

Knitcons offers a complete range of industrial silo systems suited for different materials and applications. Each type is custom-engineered based on bulk density, flow characteristics, and storage needs.

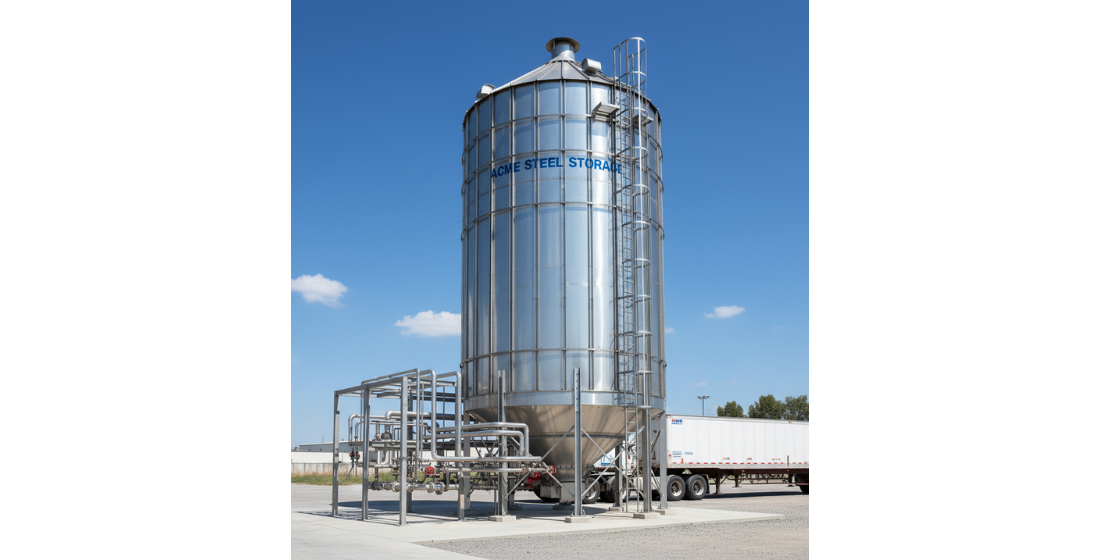

1. Stainless Steel Silo

Ideal for food, flour, and pharmaceutical industries, our Stainless steel Storage silos ensure hygienic, corrosion-resistant, and easy-to-clean storage. Perfect for flour silo systems and fine powder applications.

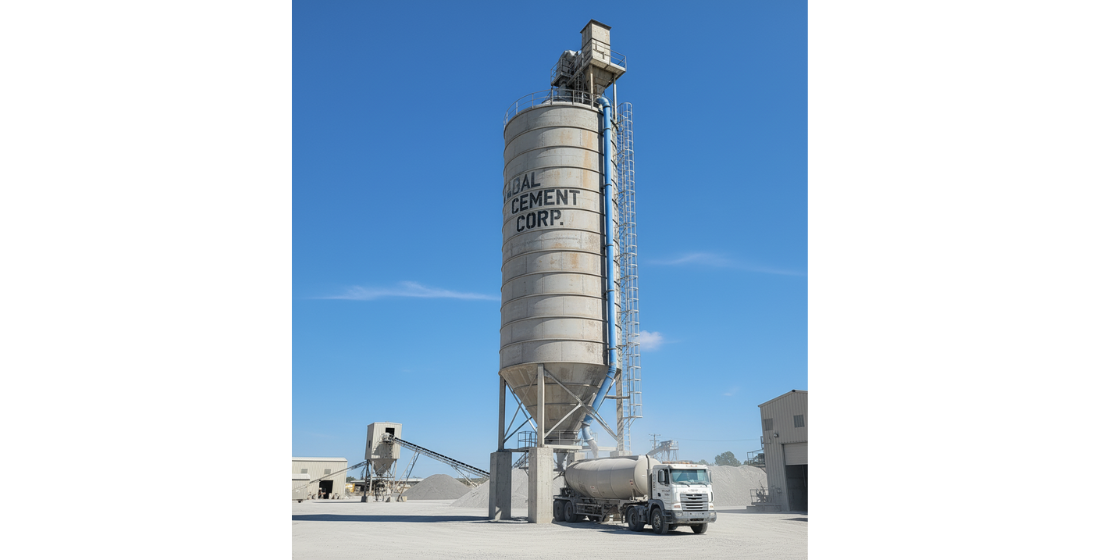

2. Cement Silos

Designed for the construction and infrastructure sector, these Concrete Storage silos provide strong, weather-resistant, and efficient storage for cement, fly ash, and lime.

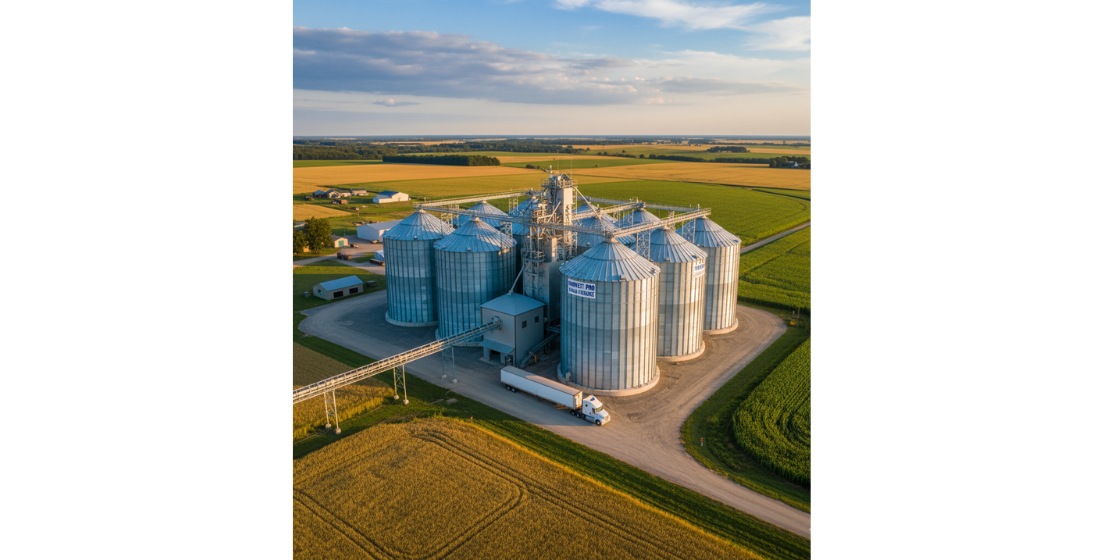

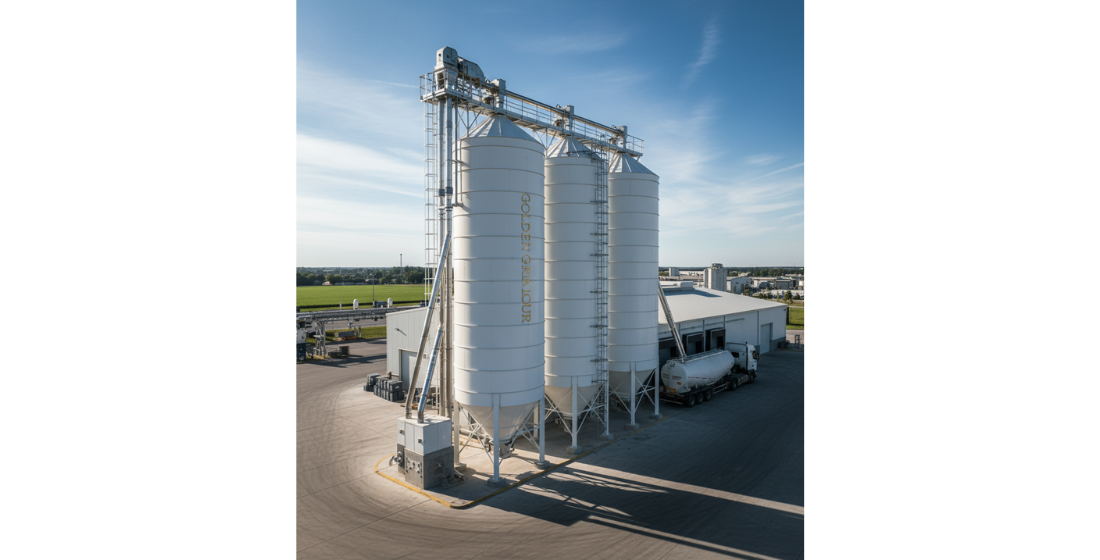

3. Grain Storage Silos

As one of the trusted grain storage silo manufacturers, Knitcons delivers silos designed for wheat, maize, rice, and pulses, ensuring temperature and moisture control for long-term preservation.

4. Chemical Storage Silo

Built with special coatings and materials, our chemical storage silos are suited for corrosive or reactive materials. Each unit is customized to meet chemical safety and environmental standards.

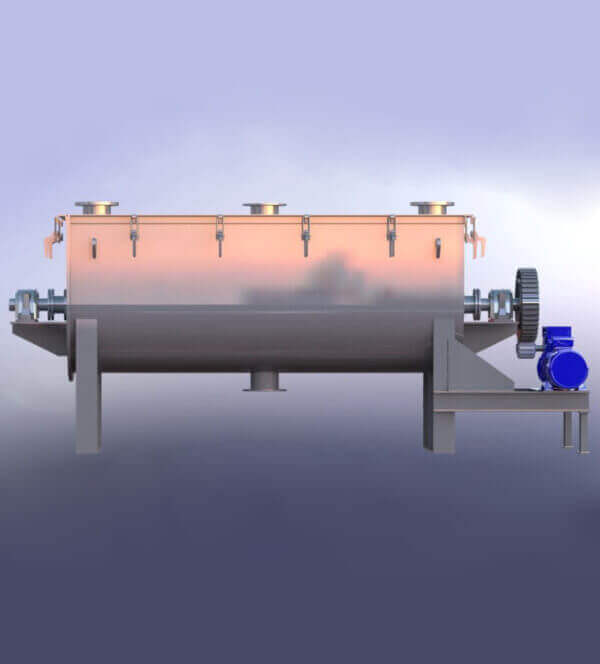

5. Flour Silo Systems

ThOur Wheat flour silo systems ensure consistent flour quality, minimal dust emission, and automated handling. Commonly used in maida mills, bakeries, and biscuit manufacturing plants.

Technical Specifications of Silo Storage System

| Parameter | Specification |

|---|---|

| Material of Construction | Mild Steel, Stainless Steel (304/316), Coated Steel |

| Capacity Range | 5 MT to 250 MT (custom-built) |

| Type | Bolted / Welded / Modular |

| Discharge Options | Gravity, Pneumatic, Slide Gate, Rotary Valve |

| Feeding Mechanism | Dense Pneumatic / Dilute Pneumatic / Screw Conveyor / Belt Conveyors |

| Monitoring Features | Level Indicators, Pressure Relief, Temperature Sensors |

Applications of Silo Storage Systems

- 1. Food & Agro Industry

For storing grains, pulses, wheat, rice, and flour, grain storage silos help maintain freshness and prevent spoilage caused by moisture or pests. - 2. Flour & Bakery Industry

Our flour silo systems are ideal for bakeries and food processors that need hygienic, dust-free, and automated flour transfer solutions. - 3. Cement & Construction Industry

Cement silos enable efficient bulk storage and pneumatic transfer of cement, fly ash, and other fine materials used in concrete batching plants. - 4. Chemical & Paint Industry

Our chemical storage silos and paint silos are designed to safely handle volatile and viscous materials, ensuring contamination-free operations. - 5. Spice and Condiments Industry

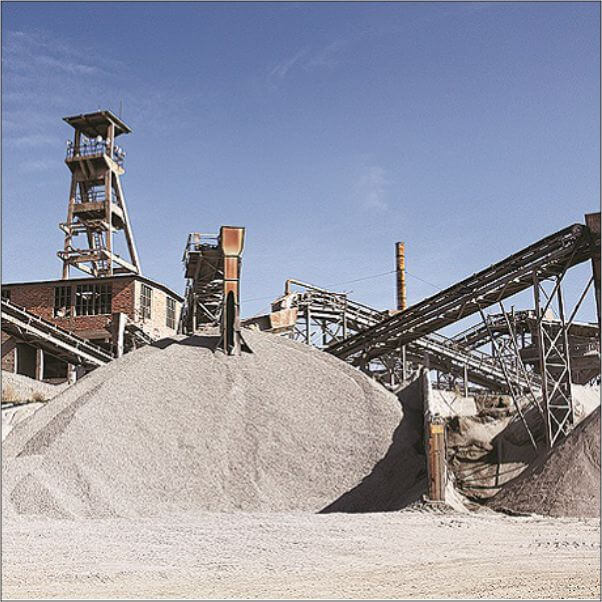

We offer customized silo storage systems for spices and powders like turmeric, chili, and coriander ensuring freshness, aroma retention, and easy flow during packaging. - 6. Mineral

Industry

Our stainless steel silos and cement silos are widely used for storing minerals like limestone powder, gypsum, and dolomite ensuring consistent quality and dust-free operation.

Why Choose Knitcons as Your Storage Silo Partner?

- 30+ years of experience in industrial storage & pneumatic conveying systems

- Turnkey design, fabrication, and installation services

- Robust quality control and after-sales support

- Expertise across food, feed, and chemical sectors

- Recognized among leading storage silo suppliers in India

Each Knitcons Maida storage silo system is equipped with advanced sensors, load cells, and discharge vibrators for accurate weight monitoring and smooth material flow.

- Require less ground space

- Minimum product contamination

- High Sanitation

- Convenient loading & depositing

- Economical compared to other storage options

- Chemical – Granules, additives, PTA powder, Sulphur etc.

- Paint & Minerals – Limestones, Calcium carbonate, Soda Ash, Tio2, Talc etc.

- Food - Wheat, Grain, Maida etc.

- Spices – Chilly, Turmeric, Coriander etc.

Trusted Powder Transfer System Manufacturer in India