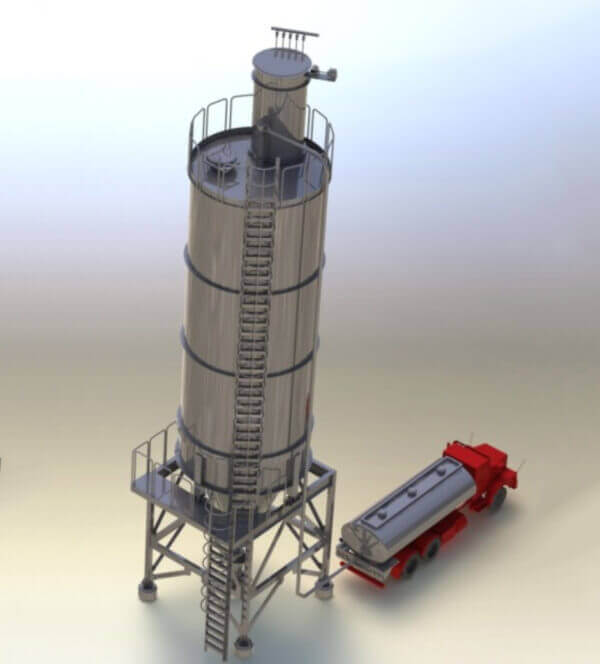

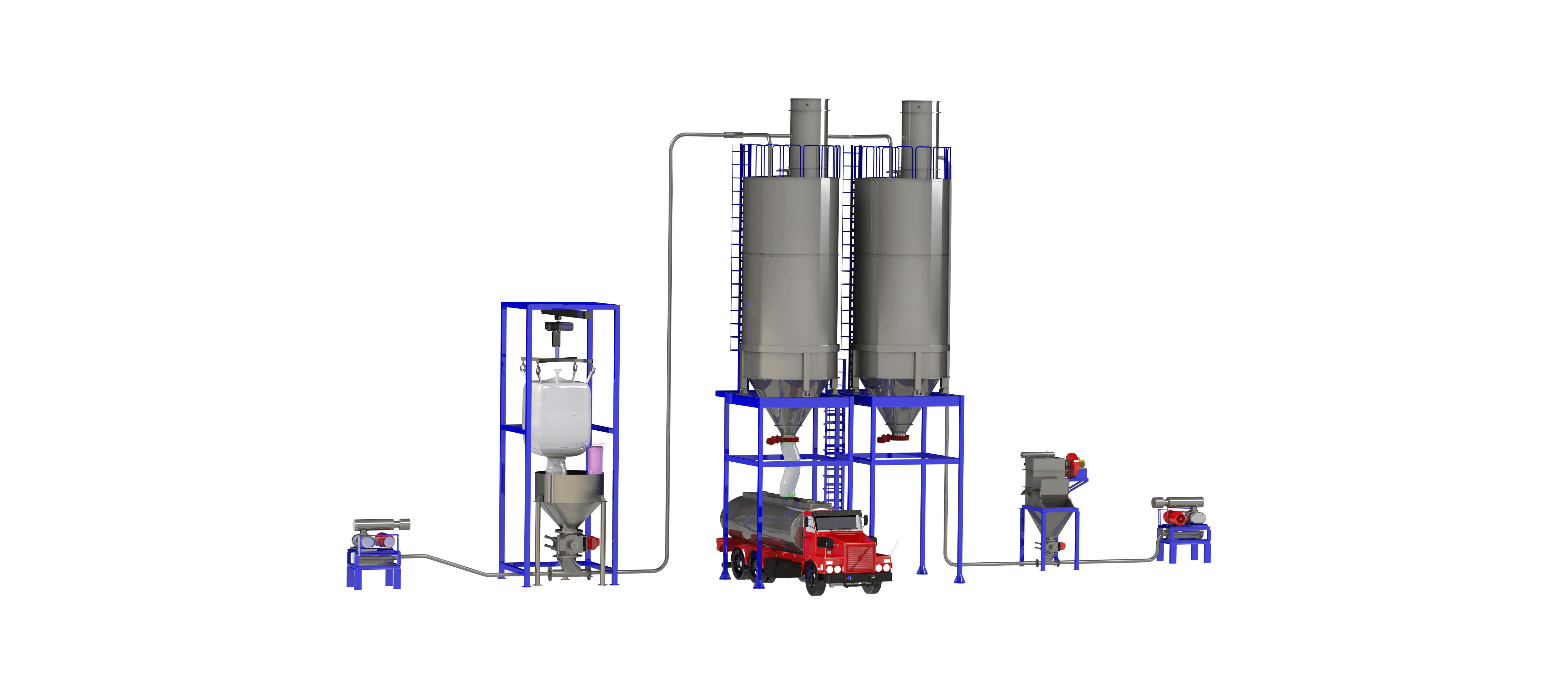

Bulk Tanker Unloading System

Bulk Tanker Unloading System for efficient and dust-free unloading of bulk materials such as Maida, Sugar, Wheat Flour, Chemicals, Minerals, and Plastics. With tanker capacities, a single operation can handle material equivalent to ~ 960 small bags or ~30 supersacks, eliminating manual handling and improving plant efficiency. Using a Tanker unloading system, materials are unloaded from road tankers and transferred directly to storage silos through a closed pipeline, ensuring contamination-free and hygienic handling. This automated process not only reduces spillage and dust but also speeds up unloading operations and enhances overall productivity. Integrated components such as vent filters, load cells, and level sensors provide precise control and dust free operation. Liquid Tanker Unloading Systems suitable for various liquids such as Palm Oil, Edible Oils, etc. The system enables smooth transfer from tankers to storage tanks through heated, insulated pipelines to maintain product consistency and prevent solidification. Ideal for industries handling bulk powders, granules & liquids, our tanker unloading solutions help achieve clean, safe, and efficient material transfer, leading to reduced labour, faster throughput, and improved operational reliability.

Bulk Tanker Loading System

Bulk tanker loading is used for dust free loading of powdered and granular bulk solids into bulk tanker trucks. Free flowing dry bulk solids in powder and granule form are easily transferred from silos, hoppers, containers and

screw feeders to tanker trucks.

Loading is possible from different equipment like silo, hopper, screw feeder, conveyors etc. Dust free working region, prevention of dust pollution, ensure plant and environmental safety.

- Reduction in labor & package cost thereby improving the loading and unloading efficiency.

- The loss rate of powder by tanker transport is about 0.5%, while it is about 2.5~5% by bags.

- Helps better to avoid humidity in Powders during storage and transport.

- Efficient and Effective Material Handling.

- Maida/Wheat Four, Seed, Corn, Rice, Sugar, Semolina, Animal feed

- Calcium carbonate, PVC, Plastic pellets

- Plastic powders, Alumina, Bentonite

- Cement, Fly ash, Mining minerals

- Marble powder, Soda ash, Sodium sulphate