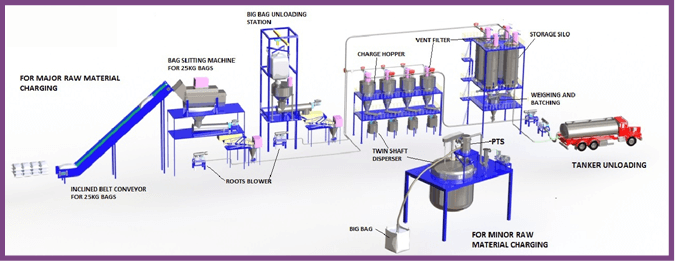

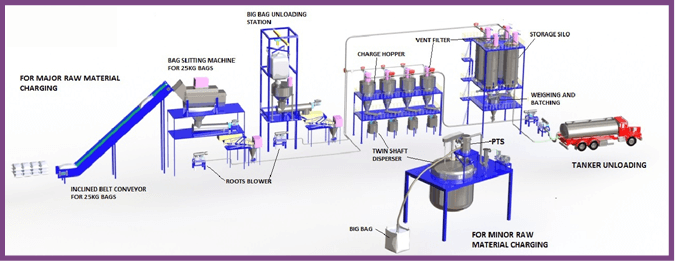

Raw material receives in 25kg, 50 Kg, 100Kg, 1000Kg Bag charging Station and

Tanker. So we offer Automatic Bag cutting machine for small Bag charging and for Big

Bag we offer Big Bag Unloading station. For Tanker we offer automatic Tanker

unloading system. So that raw material will be stored in a Storage Silo.