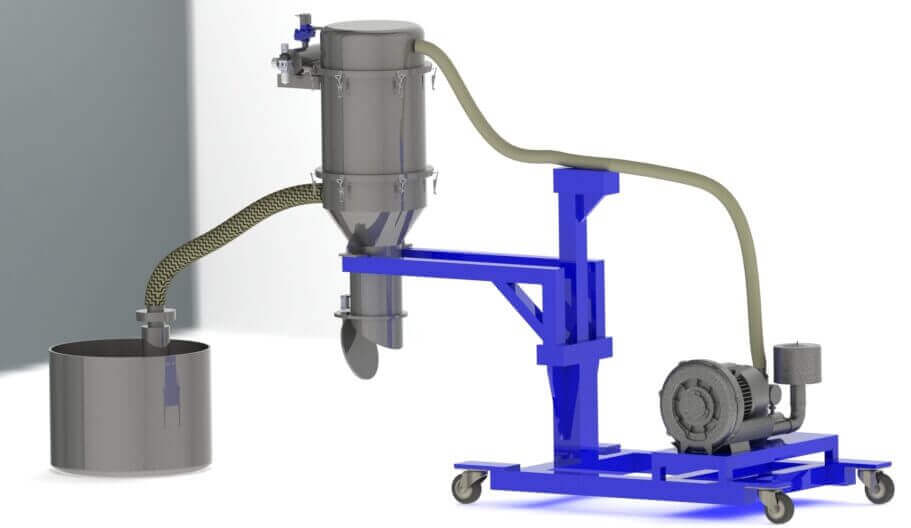

Efficient Vacuum Conveying for Powders & Granules

Knitcons’ Vacuum Powder Transfer System (PTS) is a state-of-the-art powder transfer machine

engineered to handle powders and granules with unmatched safety, efficiency, and hygiene.

Designed to replace traditional manual handling methods, our system ensures dust-free

transfer

while maintaining product integrity making it an essential solution for industries where

precision

and cleanliness are critical.

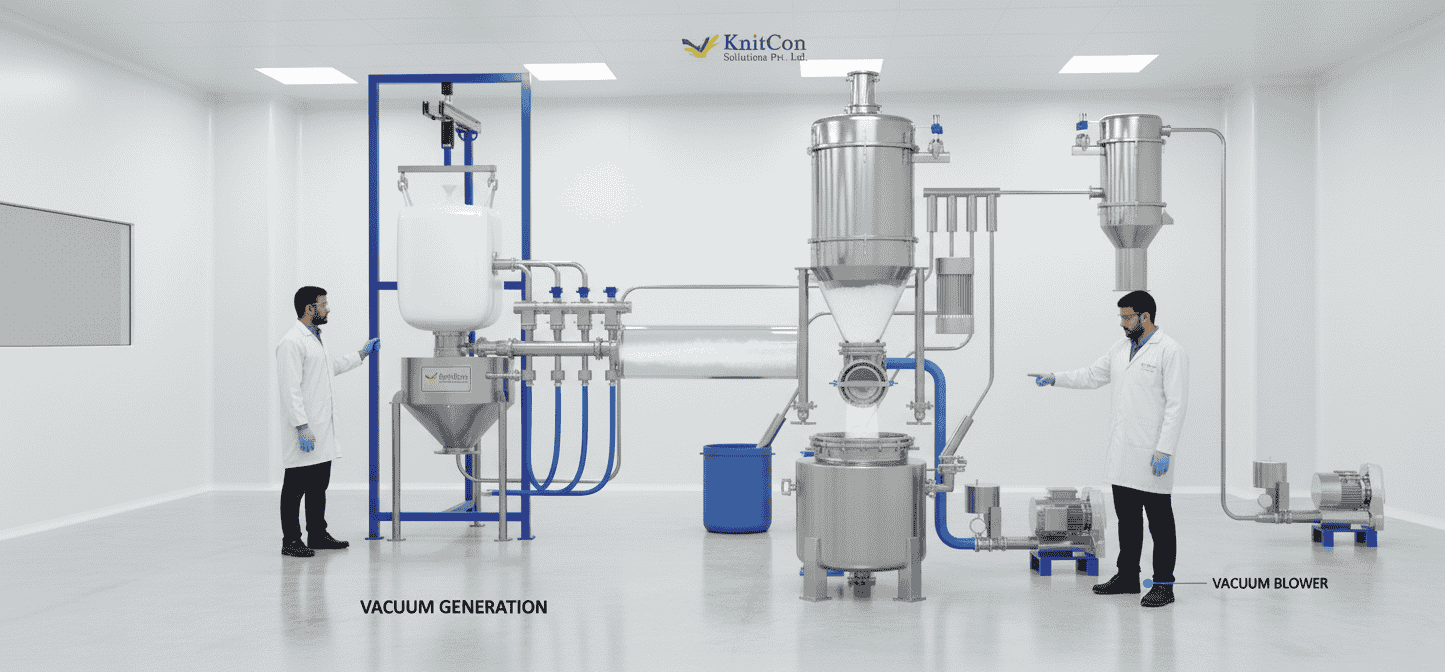

With its advanced pneumatic powder transfer system, the PTS seamlessly moves bulk materials

from multiple sources to a single destination, such as mixers, blenders, hoppers, or

reactors.

This

eliminates spillage, reduces contamination risks, and boosts overall plant productivity.

Whether you are managing fine pharmaceutical powders, sensitive food ingredients, or

industrial

chemicals, Knitcons’ bulk powder transfer systems are built to optimize your operations. By

simplifying bulk powder handling, the PTS reduces manpower requirements, ensures operator

safety, and improves process consistency.

Technical Highlights of Powder Transfer System

| SPECIFICATION | DETAILS |

|---|---|

| Transfer Capacity | 100 – 5000 kg/hr |

| Conveying Distance | Up to 40 meters |

| Pickup Options | Rotary airlock valve, suction tool, venturi |

| Integration | Standalone or with existing setup |

| Applications | Powders & granules in food, pharma, chemical, plastics, grain handling |

How It Works – Powder Transfer System Process

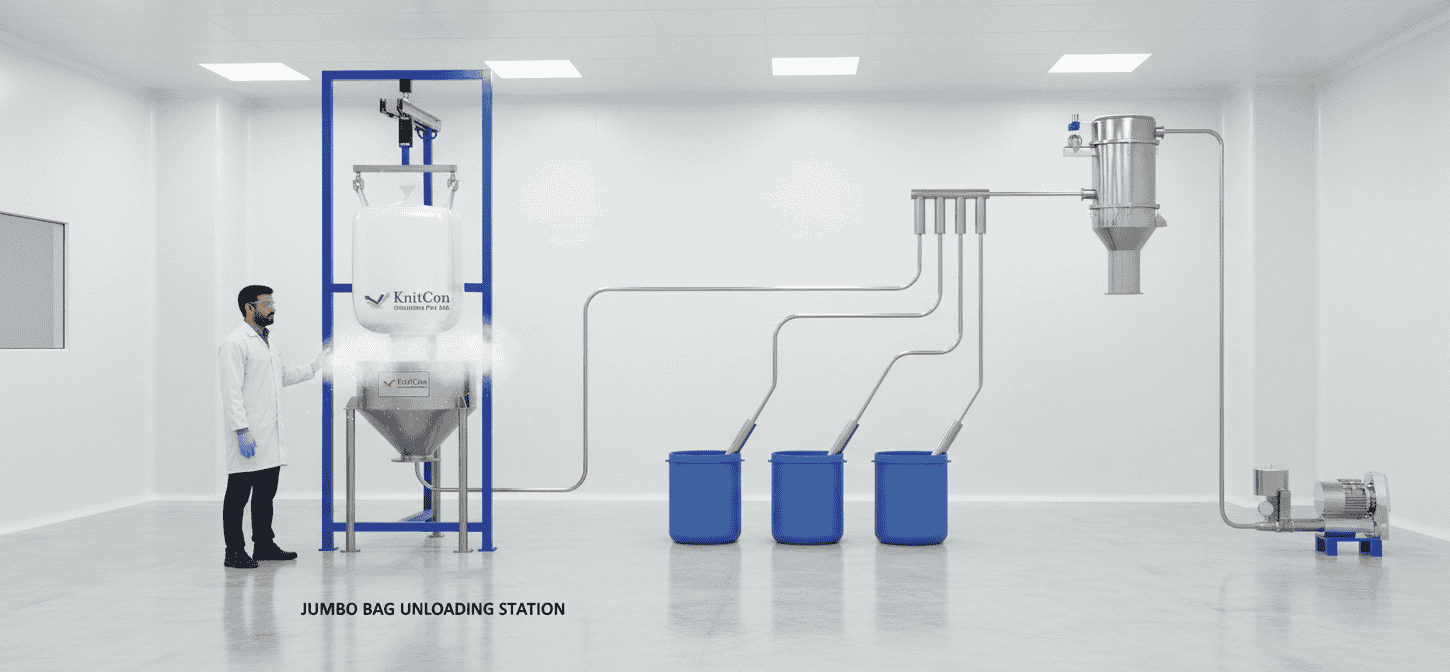

1. Material Pickup :

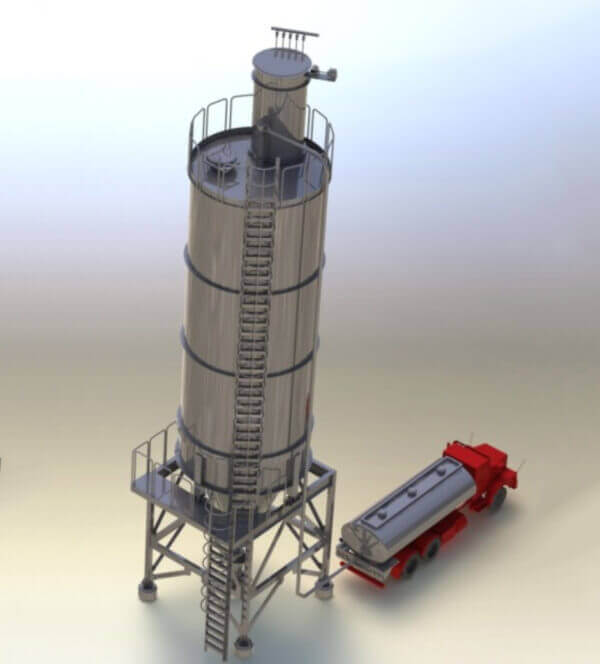

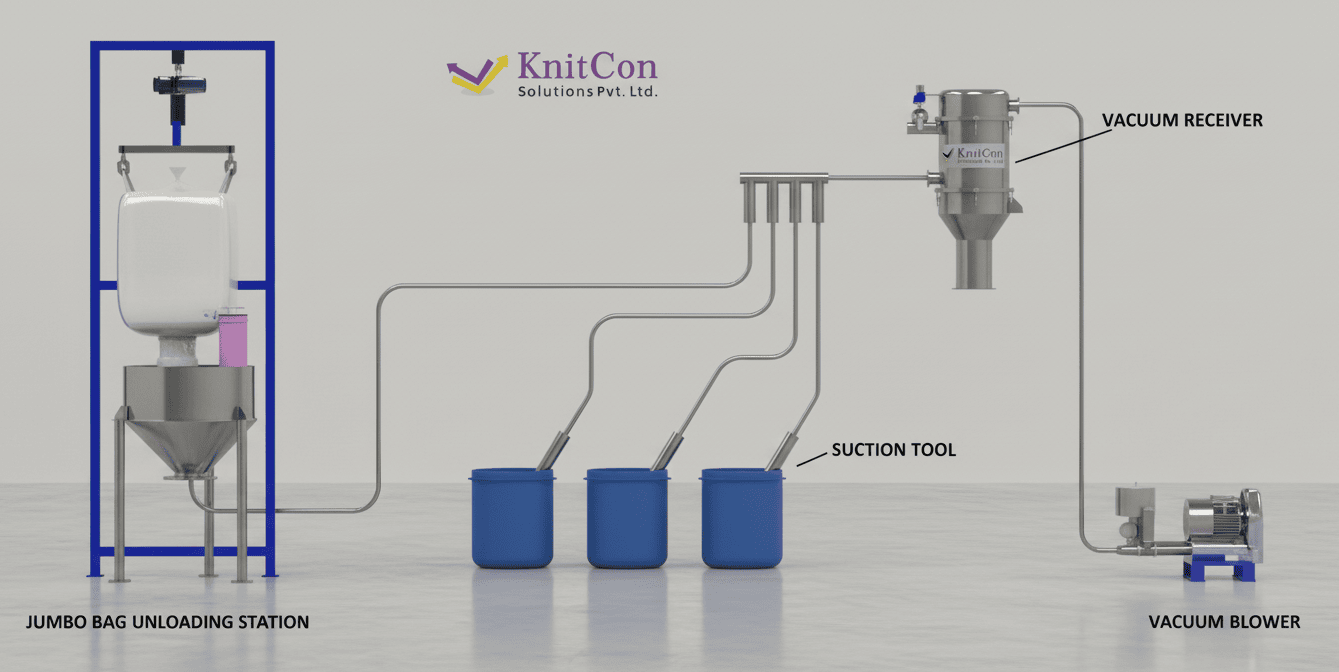

In the first step of the powder transfer system, powders and granules are efficiently drawn from bags, hoppers, storage silos, or FIBC containers using advanced vacuum suction tools. This ensures a controlled and dust-free pickup, eliminating contamination risks during material handling.

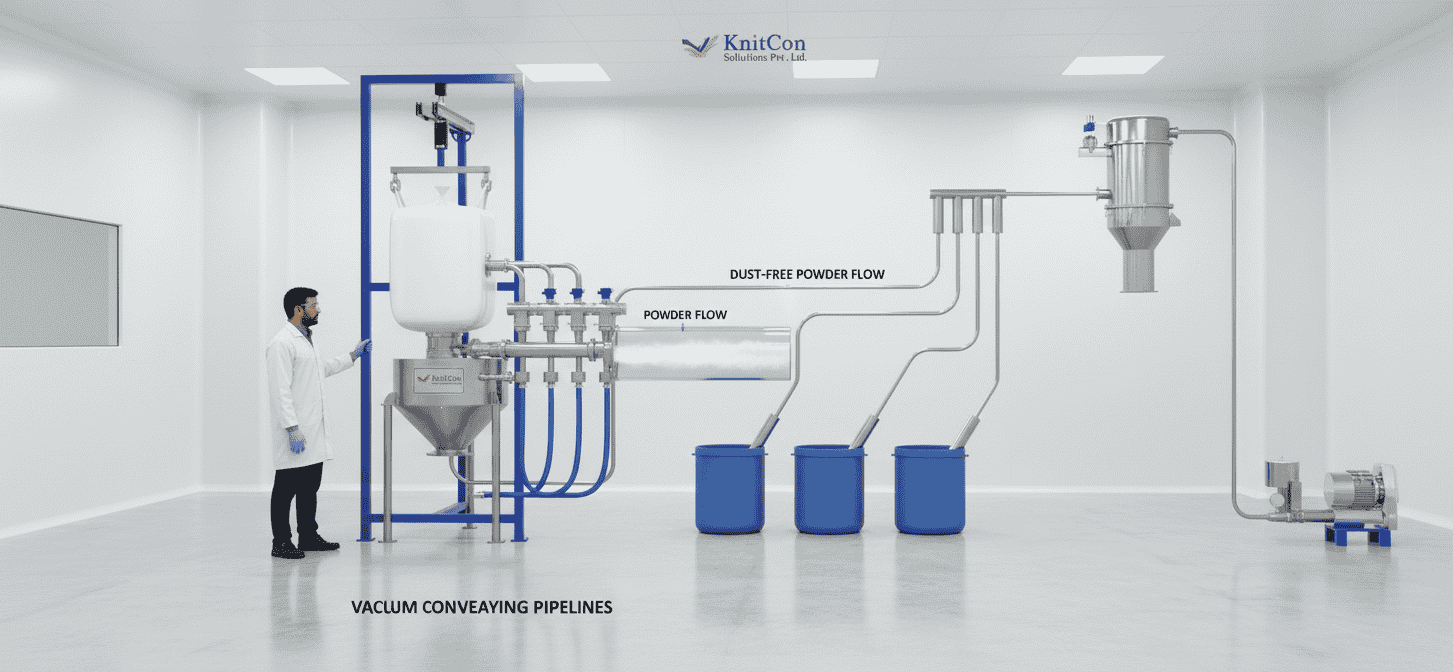

2. Vacuum Powder Conveying :

The pneumatic powder transfer system moves materials through a closed pipeline network, providing dust-free and contamination-free conveying from source to destination. This step ensures maximum product integrity and enhances operational efficiency.

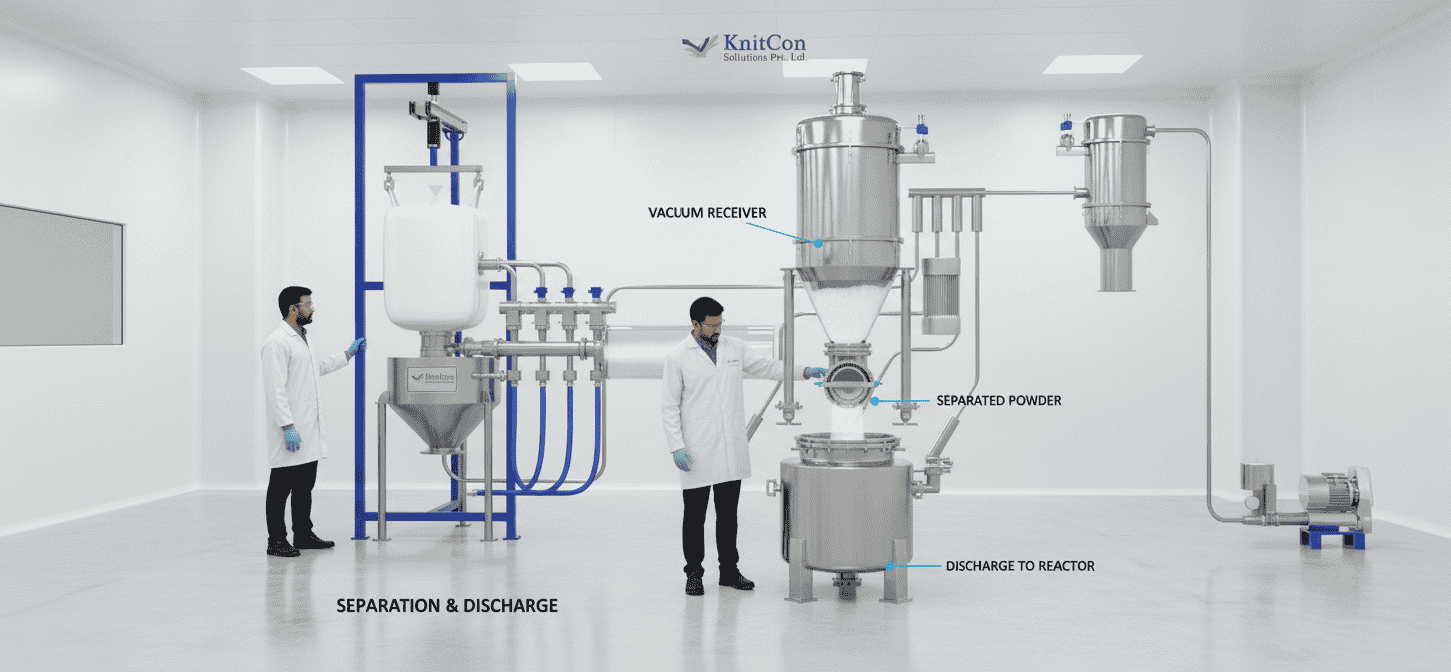

3. Discharge :

The transferred powders are discharged directly into mixers, ribbon blenders, reactors, or storage hoppers without manual handling. This seamless integration reduces product loss, prevents spillage, and improves overall plant productivity.

4. Filter & Dust Separation :

Integrated dust collectors and filters remove airborne particles, ensuring safe operation and clean air release. This feature makes the powder transfer system ideal for pharmaceutical, food, and chemical industries requiring GMP- compliant environments.

5. Flexible Operation :

The bulk powder transfer system is designed for portability, allowing easy relocation across multiple plant locations. This flexible design supports various production layouts and simplifies material handling operations.

- Easy to Clean to be replaced with Safety and hygiene

- Small Footprint - to be replaced Flexibility

- Efficient conveying method of powders transfer to be replaced with Efficiency and Accuracy

- Cost effective solution to be replaced with Reduced Labor Cost

- Food

- Pharmaceutical

- Chemical

- Plastic

- Grain Handling Industries

- Many More...

Trusted Powder Transfer System Manufacturer in India

Contact Us

Boost productivity and ensure GMP compliance with Knitcons’ bulk powder transfer systems. Contact Us Today

/1.jpg)

/2.jpg)