Mineral Industry

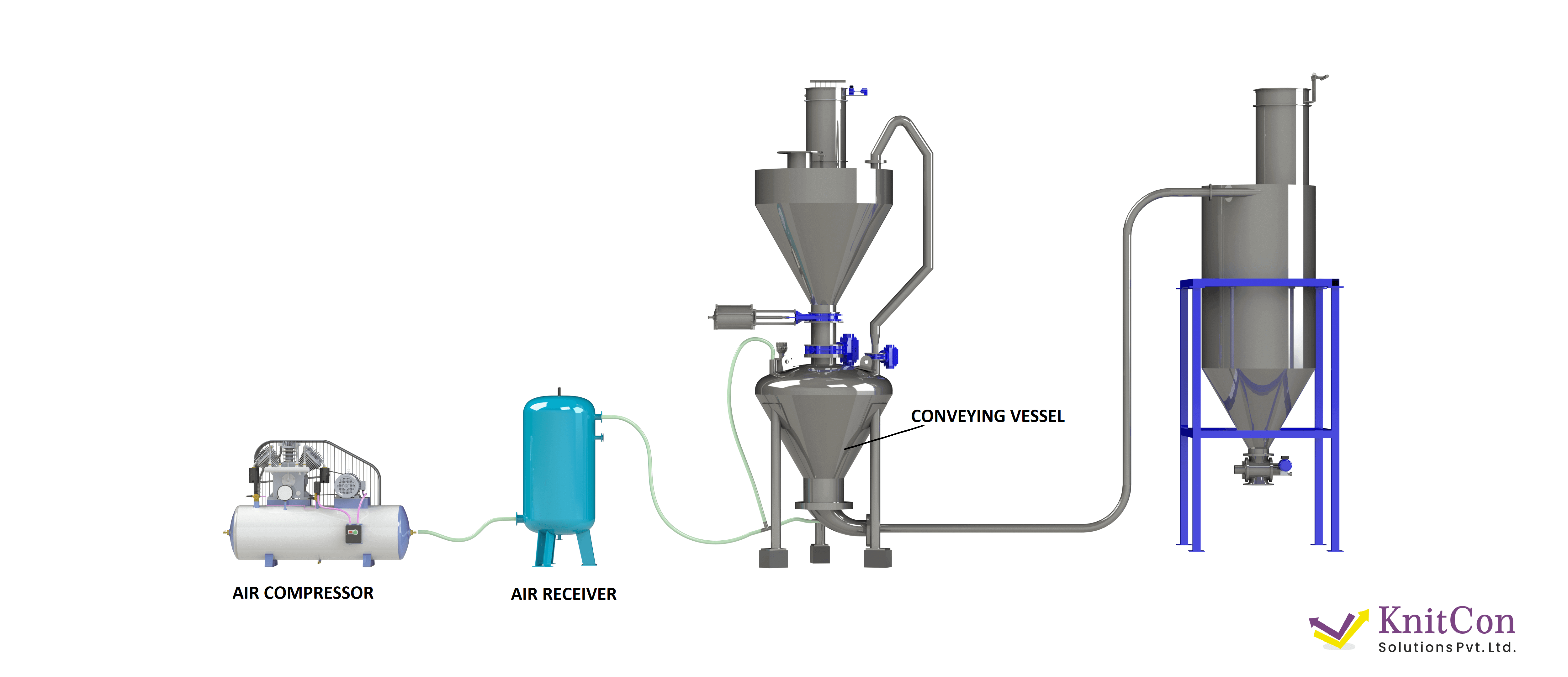

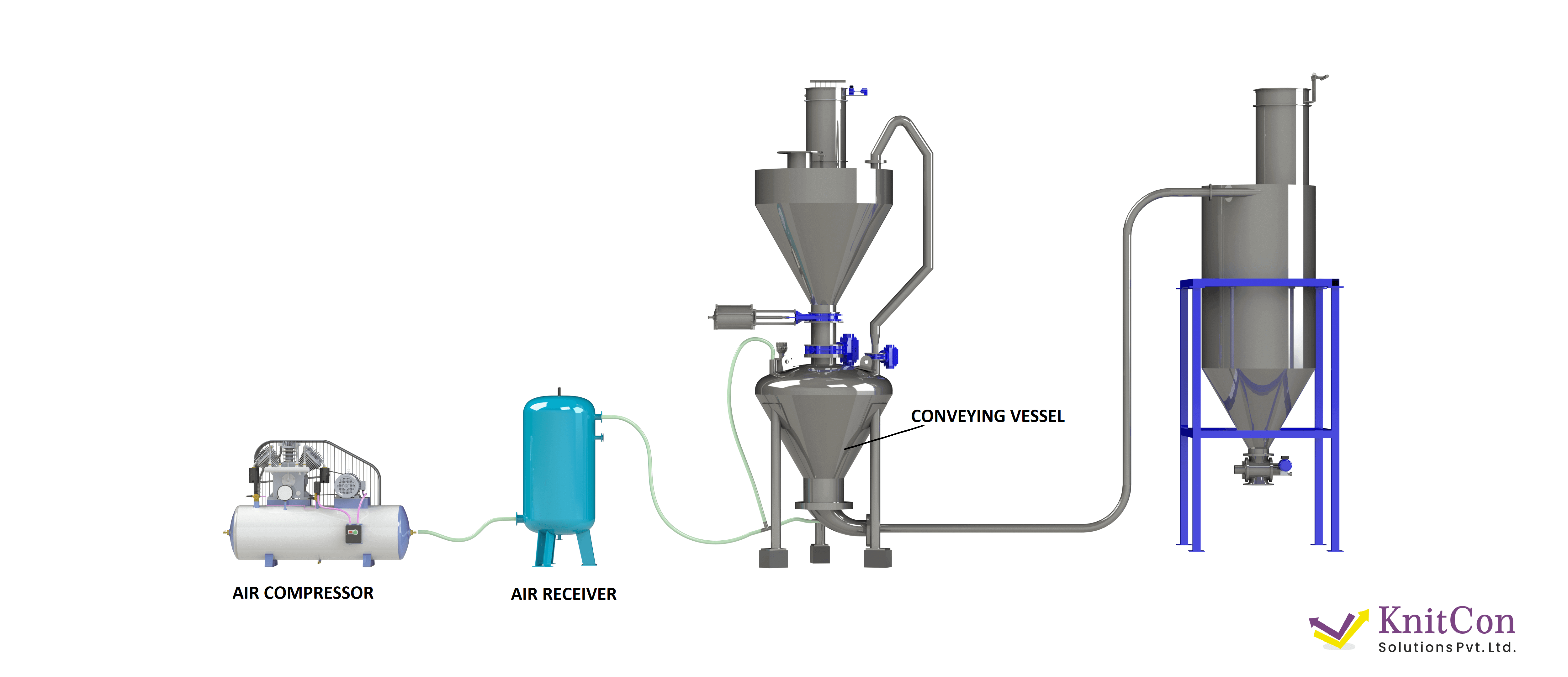

Pneumatic conveying systems are widely used in the mineral industry for transportation of materials like, ores, minerals, powders and other raw materials. These systems utilise air or other gases to transport such materials through pipes to one or multiple locations to another. One of the main advantages of pneumatic conveying systems in the mineral industry is that they offer a high degree of flexibility & efficiency in transporting materials. This is because they are designed to handle a wide range of materials, including those that are difficult to handle with mechanical conveyors. In addition to this, pneumatic conveying systems are preferred in the mineral industry since they cause less damage or wear than mechanical conveyors which is important when handling abrasive or fragile type materials.

One of the main advantages of pneumatic conveying systems in the mineral industry is that they offer a high degree of flexibility & efficiency in transporting materials. This is because they are designed to handle a wide range of materials, including those that are difficult to handle with mechanical conveyors.

In addition to this, pneumatic conveying systems are preferred in the mineral industry since they cause less damage or wear than mechanical conveyors which is important when handling abrasive or fragile type materials.

There are few types of pneumatic conveying systems that are used in the mineral industry, including dense phase conveying, dilute phase conveying, and vacuum conveying. The selection of system depends on several factors, including the properties of the material, distance of the transport, and the required flow rate.

Dense-phase conveying: In this type of system, the material is transported in a high pressure - low velocity, dense stream of air or other gas. Dense-phase conveying is suitable for materials that are more cohesive and tend to stick together.

Dilute-phase conveying: In this type of system, the material is transported in a suspension of air or other gas, which keeps the particles separated and in motion. Dilute-phase conveying is suitable for materials that are free-flowing.

Negative pressure conveying: This system operates with air pressures below atmospheric pressure. A vacuum pressure is applied at the destination to suck the material from Rotary Airlock Valve (RAL)) or through suction tool and into the air stream, With the advantage of gas leakage being inward, the dust injection into the atmosphere is virtually eliminated.