Top Sugar Grinding Machine Manufacturers in India

Knitcons Solutions the leading sugar grinding machine manufacturers in India, known for delivering precision-built, energy-efficient, and high-speed sugar grinder machines for commercial and industrial use. Our sugar grinding system are designed to transform granulated sugar into smooth, ultra-fine powdered sugar, ideal for bakery, confectionery, pharmaceutical, and food processing industries.

Whether you need a compact sugar pulverizer or a fully automatic sugar grinding plant, Knitcons Solutions ensures performance, durability, and hygiene with every machine.

Why Choose Our Sugar Grinding Machines?

- High-Speed Grinding: Fast and consistent sugar powdering.

- Premium Build Quality: Made with SS 304/316 for hygiene and strength.

- Low Dust Emission: Built-in cyclone and dust collector for clean operation.

- Customizable Output: Adjustable mesh sizes for various sugar fineness levels.

- Trusted by Industries: Preferred by food manufacturers and processors across India.

Sugar Grinding System Process

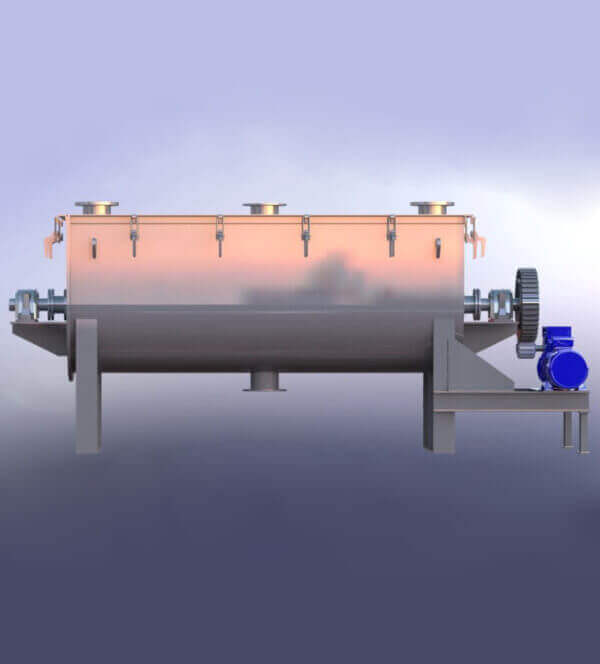

At Knitcons Solutions, our Sugar Grinding System is engineered as a closed-loop, hygienic, and energy-efficient solution for transforming crystal sugar into ultra-fine powder with consistent particle size. The process is designed for continuous, dust-free operation ensuring superior product quality.

Step-by-Step Process:

-

Raw Sugar Feeding

The process begins with feeding crystal sugar (or jaggery granules) through a screw feeder or pneumatic conveying system. The feeder ensures a steady and controlled flow of sugar into the grinder, preventing clogs or overloads. -

Pre-Screening (Optional)

If needed, a vibratory sieve or pre-sifter is used to eliminate impurities or oversized particles. This helps maintain consistency and protects the downstream equipment. -

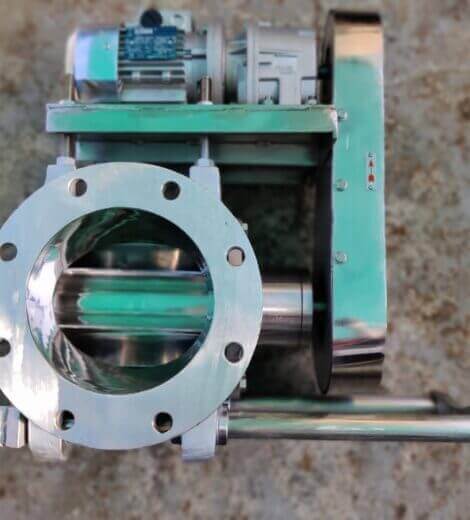

Grinding

The heart of the system is the Universal Mills, Air Classifier Mills or Hammer Mill, where the sugar is pulverized into fine powder. The high-speed rotating hammers shatter the sugar crystals by impact and shear forces, producing powder of desired fineness (up to 200 mesh).

Cooling jackets or air/nitrogen cooling systems may be used to avoid heat generation, especially for heat-sensitive sugar products like icing sugar.

-

Air Classification or Sieving

The ground sugar passes through a vibratory screen or centrifugal classifier, which separates fine particles from coarse ones. The oversize particles are automatically recirculated for regrinding. -

Dust Collection

A high-efficiency bag filter, cyclone separator, or cartridge filter captures sugar dust, ensuring a clean, dust-free environment. This also prevents product loss and maintains hygiene. -

Powder Collection and Packing

The fine powdered sugar is collected in SS bins, drums, or directly fed to packaging machines for further processing or storage.

Key Features of Knitcons Sugar Grinding System

Our systems are designed for robust performance, food safety, and operational efficiency:

-

Uniform Particle Size

- Achieves fine sugar powder up to 150–200 mesh

- Ideal for icing sugar, fondant, instant drink powders, etc.

-

Hygienic, Food-Grade Design

- SS304 or SS316 contact parts

- Easy to clean and GMP-compliant

-

Low Heat Generation

- Prevents caramelization or clumping of sugar

- Optional cooling systems for sensitive applications

-

Dust-Free Operation

- Enclosed system with efficient dust extraction

- Meets ATEX & NFPA standards for explosion protection

-

Energy-Efficient

- High throughput with low power consumption

- Designed for continuous, 24/7 operation

-

Flexible & Scalable

- Available from 100 kg/hr to 5000+ kg/hr

- Modular design for easy integration and upgrades

-

Automated Controls

- Smart PLC-based control panel

- Alarm systems, interlocks, and real-time monitoring

Applications of Our Sugar Grinder Machines

Our machines are perfect for:

- Bakeries – Producing icing or dusting sugar

- Confectioneries – For candy coatings and fillings

- Pharmaceuticals – For fine powder sugar processing

- Food Processing Plants – For ready-mix or packaged sugar products

Contact Knitcons Your Sugar Grinder Experts

As one of the top sugar grinding machine manufacturers in India, Knitcons Solutions is committed to offering innovative, reliable, and cost-effective grinding solutions tailored to your industry’s needs.

Custom Sugar Grinding Machines – Built for Your Business.