What is a Powder Transfer System?

A powder transfer system is an advanced material conveying system that moves bulk powders

from one container or processing unit to another without manual handling. Unlike

traditional

methods that rely on scooping, lifting, or manual loading, powder transfer systems use

technologies such as vacuum transfer systems or pneumatic powder transfer systems to

make the

process automated, dust-free, and efficient.

These systems are designed to ensure:

- Hygienic powder handling

- Reduction in product loss

- Safety for operators

- Compliance with GMP standards (Good Manufacturing Practices)

Benefits of Powder Transfer Systems

Using a powder transfer system offers several advantages to industries in India:

- 1.Dust-Free Operation – Prevents contamination and ensures a clean working environment.

- 2.Improved Safety – Reduces exposure of workers to harmful powders.

- 3.High Efficiency – Automates bulk powder transfer, saving time and labor costs.

- 4.Consistency – Ensures uniform powder transfer with minimal product loss.

- 5.Compliance – Meets pharmaceutical and food industry safety regulations.

- 6.Scalability – Suitable for small labs as well as large-scale manufacturing plants.

Applications Across Industries

Powder transfer systems are widely used across multiple industries in India:

- Pharmaceuticals: For transferring APIs, excipients, and powders in a sterile and dust- free way.

- Food Industry: For handling flour, sugar, spices, milk powder, and additives.

- Chemical Industry: For conveying fine chemicals, pigments, and catalysts.

- FMCG & Nutraceuticals: For producing health supplements, protein powders, and cosmetics.

By using a vacuum conveying system for powder, companies can ensure contamination-free operations while maintaining product quality.

Types of Powder Transfer Systems

Different industries require different methods of powder handling. The most common types include:

1. Powder Vacuum Transfer System

A powder vacuum transfer system uses vacuum pressure to move powders through pipelines. It is ideal for hygienic transfer and is widely used in the Indian pharmaceutical and food industries.

2. Pneumatic Powder Transfer System

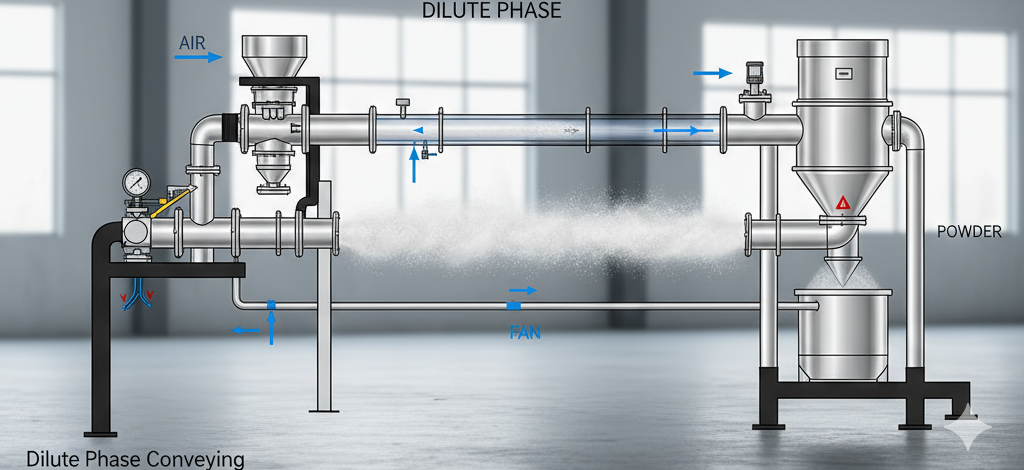

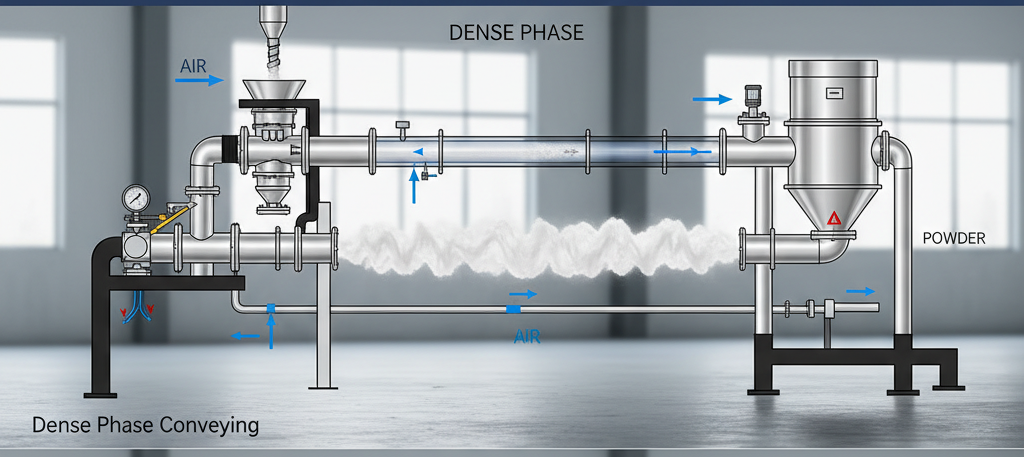

A pneumatic conveying system uses air pressure to transport powders in bulk. It is efficient for long-distance transfers and is available in dilute phase and dense phase models.

- Dilute Phase Pneumatic Conveying System – Moves powders using high air velocity, suitable for lightweight materials.

- Dense Phase Pneumatic Conveying System – Moves powders at low velocity and high pressure, suitable for fragile or abrasive powders.

3. Vacuum Conveying System

A vacuum conveying system is often chosen for applications where cleanliness, operator safety, and GMP compliance are priorities.

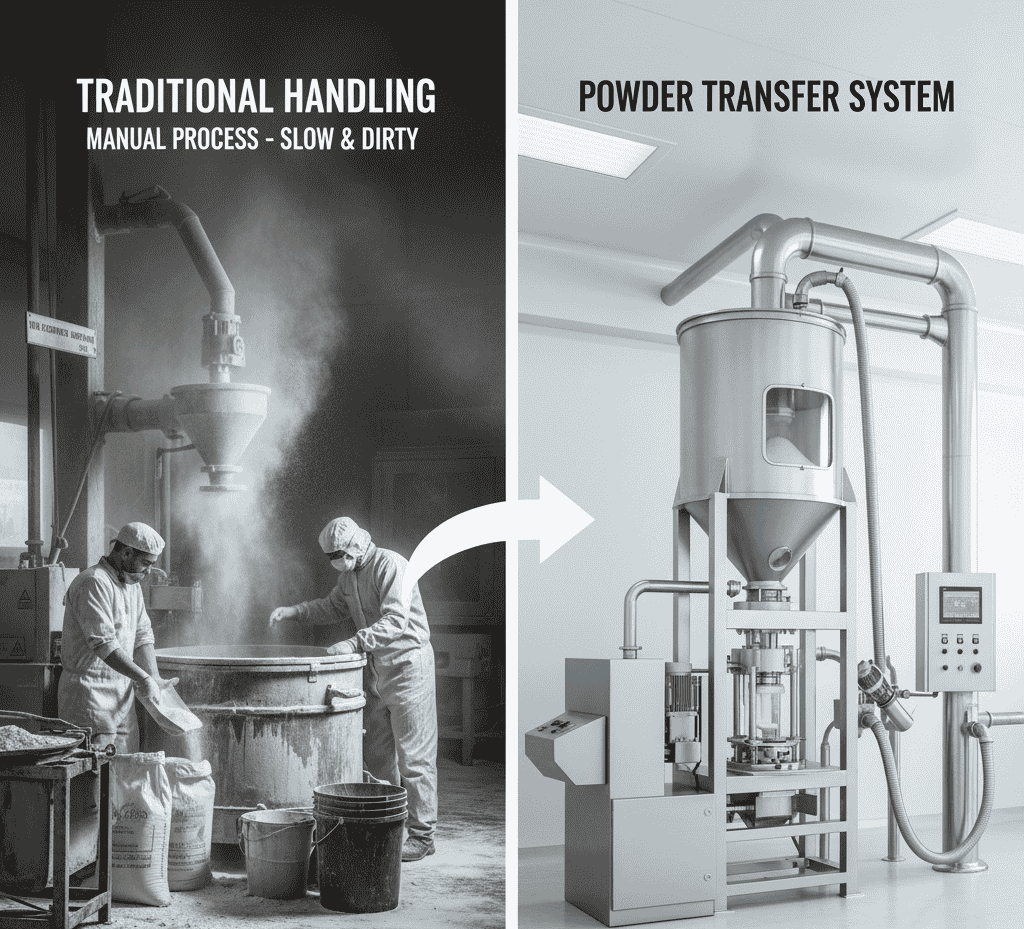

Traditional Handling vs Powder Transfer System

| Traditional Handling | Powder Transfer System |

|---|---|

| Manual scooping or lifting | Automated vacuum or pneumatic transfer |

| High risk of contamination | Dust-free, closed transfer |

| Labor-intensive | Reduces manual effort |

| Inconsistent output | Uniform and reliable transfer |

| Safety risks for workers | Safe and GMP-compliant |

Clearly, investing in a powder transfer system ensures long-term efficiency, cost savings, and compliance.

Why Indian Industries are Adopting Powder Transfer Systems

India’s growing pharmaceutical exports, booming food industry, and chemical manufacturing

demand modern material conveying systems. Regulatory compliance, automation trends, and

the

need for efficiency are driving the shift from manual handling to automated powder

transfer

systems.

Knitcon Solution the leading pneumatic conveying system manufacturers in India now offer

customized solutions, making this technology accessible for both small and large

businesses.

Conclusion

A powder transfer system is no longer a luxury it has become a necessity for Indian

manufacturers in pharma, food, and chemicals. By adopting technologies such as vacuum

transfer systems, pneumatic conveying systems, and dense phase conveying systems, industries

can ensure hygienic, efficient, and safe powder handling.

If your business is still relying on manual or outdated methods, now is the time to consider

upgrading to a modern material conveying system. Not only will this improve your

productivity,

but it will also position your company for compliance and global competitiveness.

Contact Knitcons who is leading material handling system manufacturer and supplier. Also, we

export the wet scrubber, tanker unloading, dense phase pneumatic conveying system, and

dilute

phase pneumatic conveying system as per your requirement.

FAQs

- Powder transfer systems offer:

- Dust-free and hygienic operations

- Improved safety for operators

- Consistent and efficient powder flow

- Compliance with GMP standards

- Reduced product loss

- Easy scalability for both small and large plants

- Dilute-phase conveying: Uses high air velocity to move lightweight powders over long distances.

- Dense-phase conveying: Uses low velocity and high pressure, ideal for fragile, abrasive, or heavy powders.

- Pharmaceuticals: APIs, excipients, sterile powders

- Food processing: Flour, sugar, spices, milk powder

- Chemicals: Pigments, catalysts, fine powders

- Nutraceuticals & FMCG: Protein powders, cosmetics