Introduction

Efficient bulk material handling is the backbone of industries such as cement, power generation, chemicals, fertilizers, food processing, pharmaceuticals, and mining. When large volumes of powdered, granular, or free-flowing materials must be stored safely and discharged consistently, silo storage systems become a critical industrial asset.

Modern industrial plants rely on industrial silo storage systems to ensure material safety, controlled flow, reduced losses, and seamless integration with automated bulk material handling systems. This blog explains why silo storage systems are essential and how they significantly enhance operational efficiency and compliance.

What Is a Silo Storage System?

A silo storage system is a vertical or horizontal engineered structure designed for storing bulk materials such as cement, fly ash, coal, grains, chemicals, sugar, and fertilizers. These systems are fabricated using materials like SS304 stainless steel silos, mild steel silos, or galvanized steel silos, depending on application requirements.

Industrial silo storage systems are designed to:

- Handle large storage capacities

- Maintain material quality

- Enable controlled and dust-free discharge

- Integrate with conveying and material handling equipment

Importance of Bulk Material Handling in Industries

Bulk material handling involves the storage, movement, control, and processing of materials in loose form. Inefficient handling can result in:

- Material wastage and spillage

- Dust pollution and environmental hazards

- Inconsistent material flow

- Higher maintenance and operational costs

- Workplace safety risks

This is where silo storage systems for bulk material handling play a vital role by offering a structured, enclosed, and automated storage solution.

Why Silo Storage Systems Are Essential for Bulk Material Handling

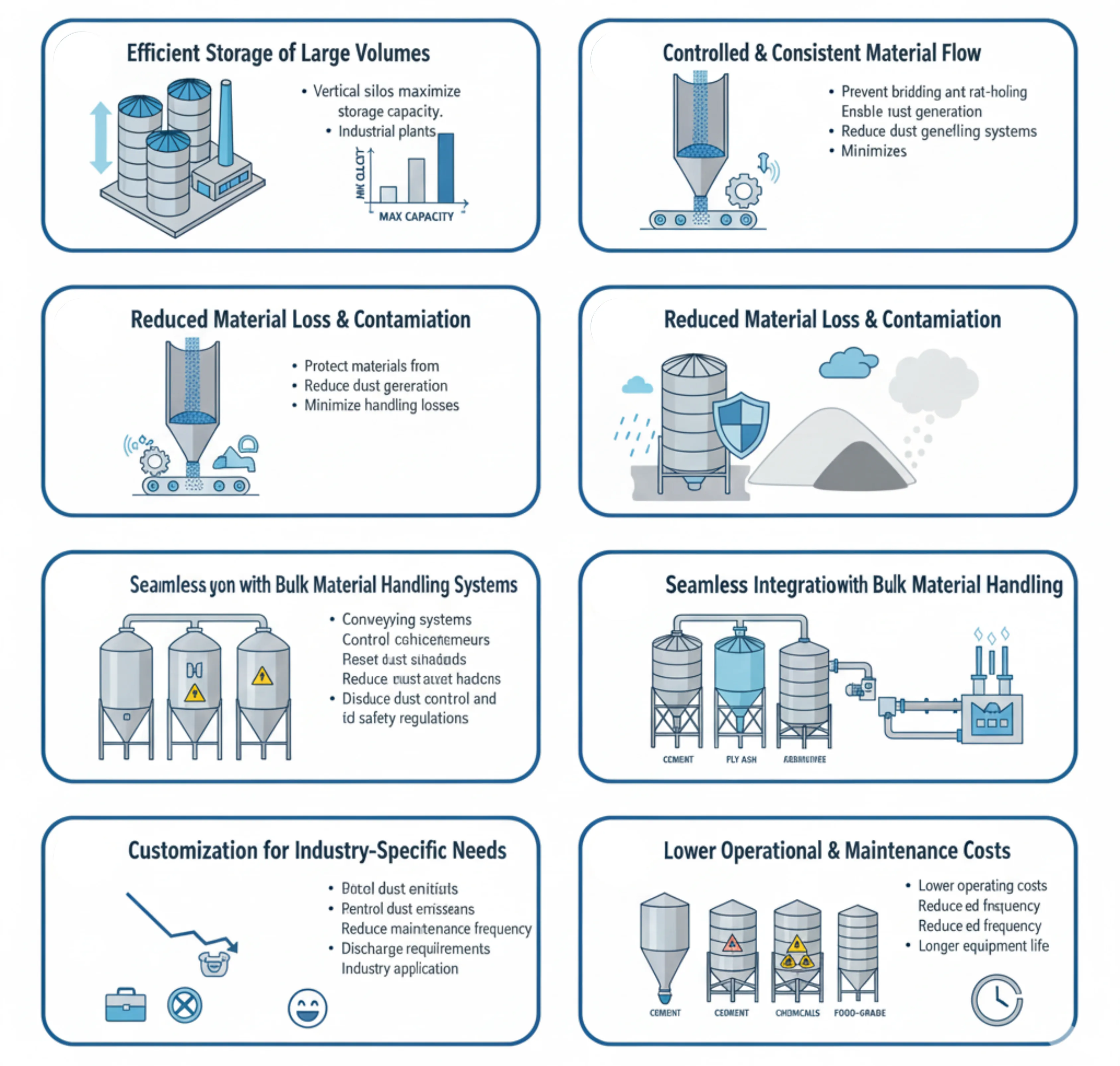

1. Efficient Storage of Large Volumes

Silo storage systems are engineered to store massive quantities of bulk materials within a compact footprint. Vertical silos maximize storage capacity while minimizing land usage, making them ideal for space-constrained industrial facilities.

2. Controlled & Consistent Material Flow in Bulk Material Handling

One of the biggest challenges in bulk material handling systems is achieving smooth and uninterrupted material discharge. Well-designed silo storage systems:

- Prevent bridging and rat-holing

- Ensure uniform material flow

- Support automated feeding and batching systems

This results in higher production efficiency and reduced downtime.

3. Reduced Material Loss & Contamination

Bulk materials are highly sensitive to moisture, contamination, and handling losses. Industrial silo storage systems:

- Protect materials from environmental exposure

- Reduce dust generation

- Minimize spillage and degradation

This is especially critical for cement, fly ash, chemicals, sugar, and food-grade materials.

4. Improved Safety & Environmental Compliance

Open storage and improper bulk handling pose serious safety and environmental risks. Silo storage systems help:

- Control dust emissions

- Improve workplace safety

- Comply with pollution control and industrial safety regulations

They support cleaner, safer, and more sustainable plant operations.

5. Seamless Integration with Bulk Material Handling Systems

Modern silo storage systems integrate smoothly with:

- Belt and screw conveyors

- Pneumatic conveying systems (Dense Phase Pneumatic Conveying Systems, Dilute Phase Pneumatic Conveying System)

- Weighing and batching systems

This integration enables automated material transfer from storage to processing with minimal manual intervention.

6. Customization for Industry-Specific Applications

Silo storage systems can be customized based on:

- Material flow properties

- Storage capacity requirements

- Discharge and aeration needs

- Industry-specific applications

From cement silos and fly ash silos to chemical, fertilizer, sugar, and grain silos, customization ensures optimal performance.

7. Lower Operational & Maintenance Costs

By reducing manual handling, dust generation, and equipment wear, silo storage systems contribute to:

- Lower operating costs

- Reduced maintenance frequency

- Extended equipment life

This makes them a cost-effective long-term investment for industrial plants.

Industries That Depend on Silo Storage Systems

Silo storage systems are widely used in:

- Cement & construction industries

- Power plants and thermal stations

- Fertilizer & chemical processing plants

- Food, grain & sugar handling facilities

- Mining & mineral processing units

- Pharmaceutical manufacturing

Each industry relies on efficient bulk material handling to maintain quality, productivity, and compliance.

How to Choose the Right Silo Storage System

Selecting the right silo storage system depends on:

- Material type and flow behavior

- Required storage capacity

- Environmental and climatic conditions

- Integration with existing bulk material handling systems

Partnering with an experienced industrial silo manufacturer ensures reliable design, fabrication, installation, and after-sales support.

Why Choose KnitCons for Silo Storage Systems?

KnitCons offers custom-engineered silo storage systems designed to meet diverse industrial requirements. With expertise in bulk material handling solutions, KnitCons delivers:

- Robust and durable silo designs

- Compliance with safety and environmental standards

- Seamless system integration

- Long-term operational reliability

Conclusion

Silo storage systems are more than just storage structures they are a core component of efficient bulk material handling. By improving storage efficiency, ensuring controlled material flow, enhancing safety, and reducing operational costs, silo storage systems play a vital role in modern industrial operations.

Investing in the right silo storage system ensures smoother processes, higher productivity, regulatory compliance, and sustainable industrial growth.

Need a customized silo storage solution? Talk to Knitcon Solution for bulk material handling.